How Does a Sewing Machine Work?

At one time, all mothers taught their daughters to sew. Today that is no longer true, and although almost everyone has seen a sewing machine, many people use one only rarely, if at all. Unless you're interested in a career in fashion design or sewing machine repair, chances are you haven't had much reason to use one. So you may not know that a sewing machine is a miracle of intricate, old-fashioned mechanical technology.

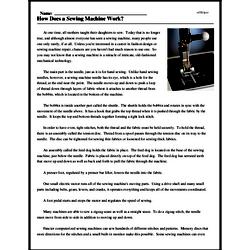

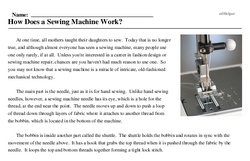

The main part is the needle, just as it is for hand sewing. Unlike hand sewing needles, however, a sewing machine needle has its eye, which is a hole for the thread, at the end near the point. The needle moves up and down to push a loop of thread down through layers of fabric where it attaches to another thread from the bobbin, which is located in the bottom of the machine.

The bobbin is inside another part called the shuttle. The shuttle holds the bobbin and rotates in sync with the movement of the needle above. It has a hook that grabs the top thread when it is pushed through the fabric by the needle. It loops the top and bottom threads together forming a tight lock stitch.

In order to have even, tight stitches, both the thread and the fabric must be held securely. To hold the thread, there is an assembly called the tension disc. Thread from a spool passes through the tension disc on its way to the needle. The disc can be tightened for sewing thin fabrics or loosened for sewing thick fabrics.

An assembly called the feed dog holds the fabric in place. The feed dog is located on the base of the sewing machine, just below the needle. Fabric is placed directly on top of the feed dog. The feed dog has serrated teeth that move up and down as well as back and forth to pull the fabric through the machine.